DC Motor Interfacing With Micrcontroller

DC Motors are small, inexpensive and powerful motors used widely in robotics for their small size and high energy out. A typical DC motor operates at speeds that are far too high speed to be useful, and torque that are far too low. Gear reduction is the standard method by which a motor is made useful .Gear’s reduce the speed of motor and increases the torque.

Choosing a DC Motor Depends on application.Prefer following:

- DCMotor with Gear head

- Operating voltage 12V

- Speed

Drive basics of DC Motor

| Red wire | Black wire | Direction of rotation |

| Positive | Negative | Clock wise |

| Negative | Positive | Anti clock wise |

| Logic | Logic | Direction |

| 1 | 0 | Clock |

| 0 | 1 | Anti clock |

| Direction | Pulse to |

| Clock wise | A and C |

| Anti Clock wise | B and D |

Bi-Direction control of DC Motor

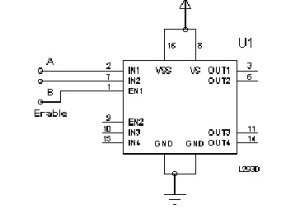

H-Bridge Circuit using transistors for bidirectional driving of DC motor. H-Bridges in IC’s to reduce the drive circuit complexity . L293D is a dual H-Bridge motor driver, So with one IC we can interface two DC motors which can be controlled in both clockwise and counter clockwise direction and if you have motor with fix direction of motion the you can make use of all the four I/Os to connect up to four DC motors. L293D has output current of 600mA and peak output current of 1.2A per channel. Moreover for protection of circuit from back EMF ouput diodes are included within the IC. The output supply (VCC2) has a wide range from 4.5V to 36V, which has made L293D a best choice for DC motor driver.

As you can see in the circuit, three pins are needed for interfacing a DC motor (A, B, Enable). If you want the o/p to be enabled completely then you can connect Enable to VCC and only 2 pins needed from controller to make the motor work.

As you can see in the circuit, three pins are needed for interfacing a DC motor (A, B, Enable). If you want the o/p to be enabled completely then you can connect Enable to VCC and only 2 pins needed from controller to make the motor work.

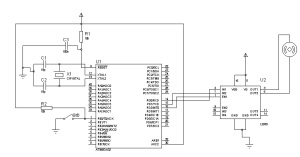

**To Move the motor Clockwise And Anticlockwise,Must be use two separate Power source,one for microcontroller and another for driving motor with Driver IC.

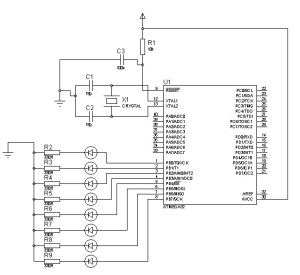

Here,i have used ATMEGA32 micrcontroller and Code is written in C using AVR Studio 5.0.

Source Code

/*

* DCMotorControl.c

*

* Created: 4/1/2011 12:08:10 AM

* Author: sfg

*/

#include <avr/io.h>

#include <util/delay.h>

int main(void)

{

DDRD=0xFF; //PORTD declared as output

PORTD=0x00;

DDRB=0x00; //PORTB as input

while(1)

{

//Pin 0 of PORTB high,then Moves Clockwise

//A–1–PD0

//B–0–PD1

//Enable–1–PD2

if(PINB==0x01)

{

PORTD=0x05;

//_delay_ms(5000);

}

//Pin 0 of PORTB Low,then Moves AntiClockwise

//A–0–PD0

//B–1–PD1

//Enable–1–PD2

else

{

PORTD=0x06;

//_delay_ms(5000);

}

}

}

Recent Comments